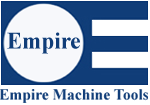

VACUUM INDUCTION MELTING FURNACES (VIM)

Processing Application:

– Equiaxed/Directional Soldification/Single Crystal Casting

– Alloy casting

– Electrode casting

– Cold Wall Induction casting (CWI)

Advantages:

– Combination DS/SC/Equiax equipment offers industry’s fastest process conversion

– Multi-zone mold heaters

– One- or two-axis precision pouring (auto teach, profile and constant volume)

– Precisiontemperature measurement (OPTO-TC)

– Closed loop solidification control

– Door-mounted furnace melt box assemblies

– Horizontal bar feeder assembly includes X-Y motion control for simultaneous loading of bars and liners or alternate bar loading via rotation

– Unmanned startup and/or shutdown of vacuum equipment (Sentry package)

– Video systems provide improved process monitoring and control

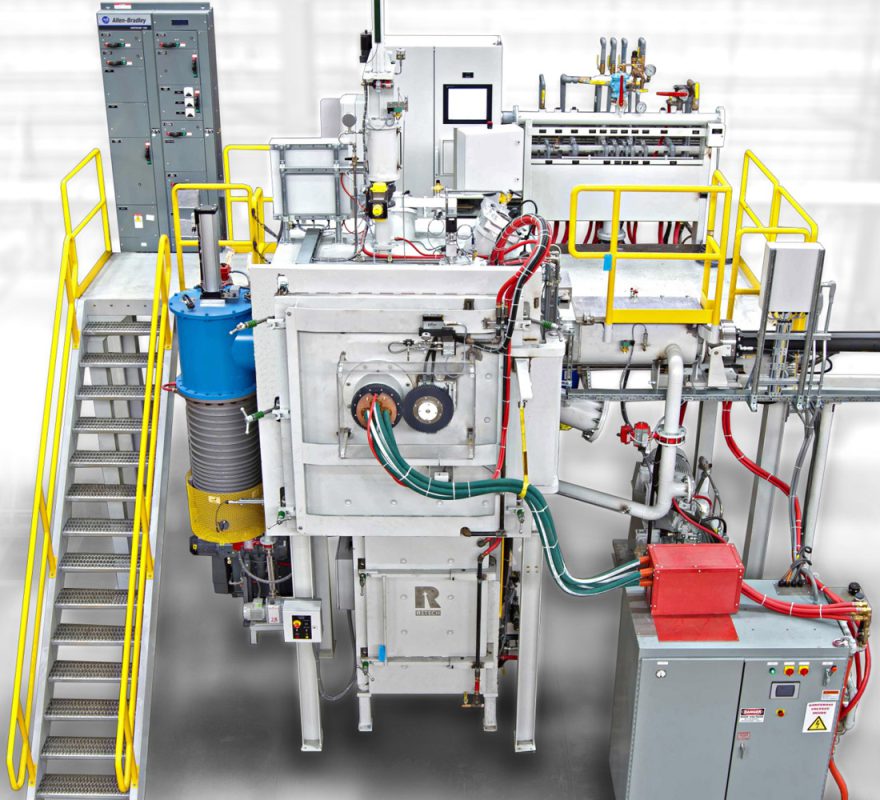

VACUUM ARC REMELT FURNACES (VAR)

Processing Application:

Ingots: Titanium, Steel, Nickel, Zirconium, Tantalum, Tungsten, Niobium

Advantages:

– Furnace design minimizes facility height requirements

– Typical ingot sizes range from 2″ to 50″ diameter (50 to 1,270 mm)

– Typical power capacities from 500 amps to 50,000 amps

– Highly accurate weight monitoring system

-X-Y electrode positioning

– Fully coaxial power entry available on all Retech VAR melters

-State-of-the-art controls with sophisticated algorithms and controls capabilities for voltage, drip short and melt rates

-Comprehensive data acquisition systems for complete melt histories

– Box column rotation

– Smooth and accurate ram position control

ELECTRON BEAM FURNACES (EB)

Processing Application:

-Ingots, Slab

– Scrap Consolidation Hearth Melting

– Hearth Malting

– Electron Beam Welder

Advantages:

– Includes Von Ardenne Electron Beam Guns

– Wide size range; typical 2-½ inches to 36 inches diameter (60 mm to 900mm) ingots, as well as jumbo slab production

– Multi-gun power from 80 kW to 5000 kW

-Systems of single or multiple gun design

– Winbeam® computerized beam controller offers user-friendly furnace automation

– Accepts a variety of feed material configurations, such as scrap, sponge and bar

– Offers significant cost savings by eliminating electrode welding and the consumable arc processing

– Electron beam cold hearth melting proven to eliminate high density and low density inclusions in titanium alloys

PLASMA ARC FURNACES (PAM)

Processing Application:

– Ingots, Slab, Powder Production

– Scrap Consolidation

– Hearth Melting Powder

– Plasma Welders

Advantages:

– Fine-grain ingot microstructure

– Maintains chemical composition of complex alloys

-Plasma cold hearth melting proven to eliminate high-density and low density inclusions in titanium alloys

-WinTorch® computerized torch motion profilers offer user-friendly furnace automation

-Accepts a variety of feed material configurations, such as scrap, chips, sponge, compacts and bars

-Offers significant cost savings by eliminating electrode welding and primary consumable arc processing

– Torches operable on a variety of gases, including helium, argon, nitrogen and hydrogen

-Gas recovery and reuse systems with full range of capacities available

– High throughput refining technology Typical power from 75 kW to 3000 kW Wide product range; typical sizes 2-½ inches to 36 inches diameter (60 mm to 900 mm) ingot capacities

POWDER PRODUCTION EQUIPMENT

Processing Application:

– Battery Alloys

– Magnet materials

– Aerospace material

Advantages:

– Laboratory- to production-scale units available

– Spherical powder 10 microns and larger

-Thin strip casting capabilities

– Typical production rates from 1 to 20 pounds per minute (5 to 9 kg)

– Rapid solidification process